In line with our vision, our biotechnologies…

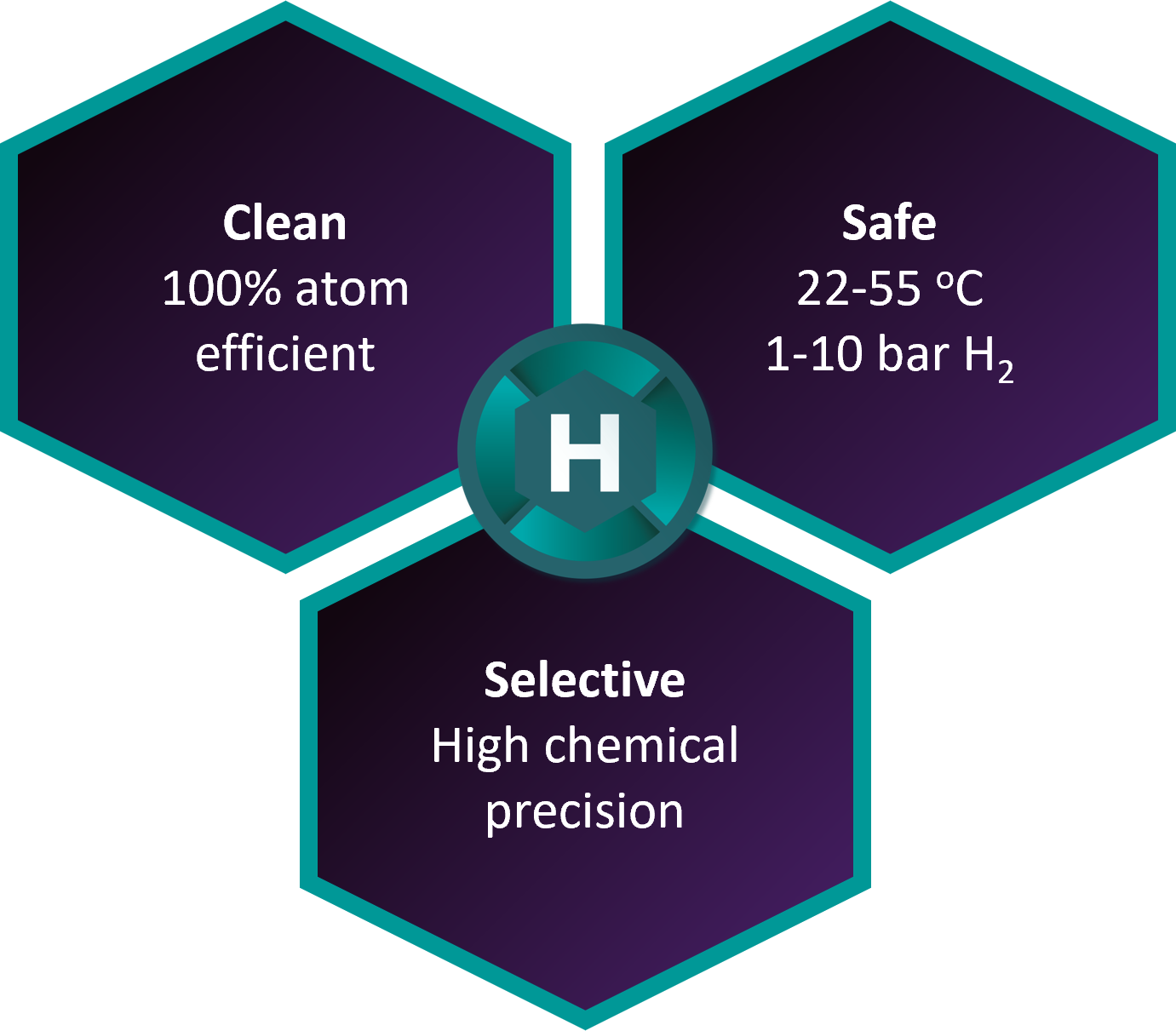

Replace metals: Our biotechnologies allow ‘hydrogenation’ reactions to run under mild conditions (temperature, pressure) and benefit from the exquisite precision of redox biocatalysis.

Decarbonise biocatalysis: We believe that improving implementation of redox biocatalysis will ultimately speed up a switch to bio-based feedstocks, building circular and bio-based economies.

Our pioneering biomanufacturing solutions

bring together the best of biology and chemistry for cleaner, safer, cheaper chemical production, and make use of existing chemical manufacturing infrastructure allowing us to compete on lower barriers-to-entry.

Our evaluation products put you in control

If you are interested to get started with our biocatalytic hydrogenation technologies, why not get in touch?

These products have been demonstrated in continuous flow reactors including the H-cube (ThalesNano) and AM Technology ACR.

Our Bio2Amine products are being showcased for generic APIs such as Paracetamol production. See our 1-pager here, and email for more information.

Technology showcases

Bio2Amine

This heterogenous biocatalyst shows excellent scope, selectivity and productivity for nitro-to-amine conversions. Some of the academic work has been published and our work at HydRegen is aligned with rapid scalability and intensification.

Technology showcases

A key step in manufacture of paracetamol is reduction of p-nitrophenol to generate an amine.

Our Bio2Amine product provides a safer, more sustainable bio-process that can be implemented in batch or continuous flow infrastructure.

Check back soon for more detailed substrate scope, intensification of processes and opportunities for new partnerships.

Technology showcases

Quinuclidinol

Quinuclidinol is a key API intermediate, accessed with excellent enantio-selectivity by an NADH-dependent ketone reductase (AtQR).

Implementation with HydRegen technology provides a decarbonised biomanufacturing route that can be readily intensified and scaled via existing infrastructure for catalytic hydrogenation.

To find out more, see our product guide below or email: products@hydregenoxford.com

p-aminophenol (towards paracetamol)

A key step in manufacture of paracetamol is reduction of p-nitrophenol to generate an amine.

Our Bio2Amine product provides a safer, more sustainable bio-process that can be implemented in batch or continuous flow infrastructure.

Check back soon for more detailed substrate scope, intensification of processes and opportunities for new partnerships.

Let’s get down to detail

Experienced in redox biocatalysis?

Hydrogen-powered NADH recycling

To use an NADH-dependent biocatalyst at scale, a cofactor recycling system is required. Our patent-protected biotechnology comprises robust enzymes, immobilised on carbon, for hydrogen-powered NADH recycling. Once combined with your NADH-dependent enzyme, the overall reaction is 100% atom efficient:

no waste, no pH control, minimal clean up!

Experienced in catalytic hydrogenation?

Biocatalytic hydrogenation

We are also developing complete solutions, allowing you to carry out a range of chiral reductions without needing any prior experience with biocatalysis. Coming from a chemistry background, we have focused on ensuring that our biocatalyst systems can be handled in the same ways as carbon-supported metal catalysts. Whilst operation in typical batch reactors is enabled, the real step-change is our ability to operate in your existing hydrogenation flow reactors.